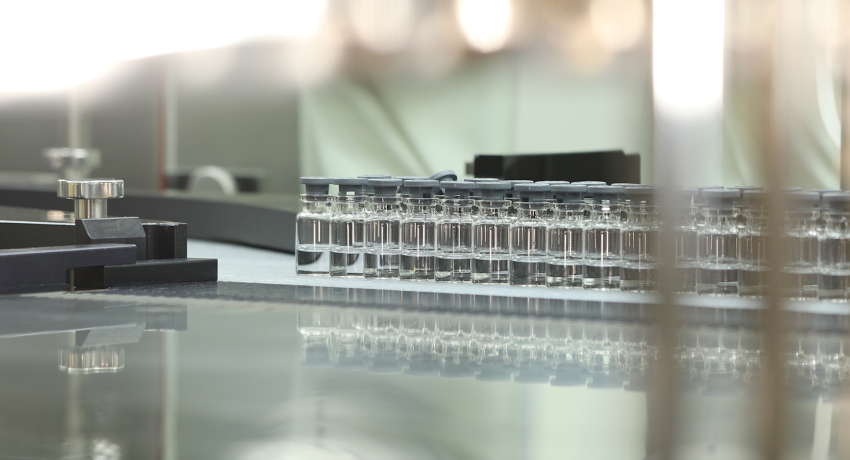

Pharmaceutical manufacturing is evolving. Traditional batch processing, with its frequent stops and inefficiencies, is being replaced by continuous manufacturing. This modern approach streamlines production, improves quality, and reduces costs. For equipment suppliers, service providers, and engineering firms, this shift presents both opportunities and challenges.

Why Continuous Manufacturing is the Future

Increased Efficiency

Unlike batch processing, which requires starting and stopping between production stages, continuous manufacturing runs smoothly without interruptions. This eliminates bottlenecks, speeds up production, and allows manufacturers to respond faster to market demand.

Improved Product Quality

Continuous manufacturing integrates real-time monitoring and automated adjustments, ensuring consistent quality throughout production. By minimizing human intervention and variability, companies can achieve higher compliance with regulatory standards and reduce waste.

Cost Savings

By optimizing material use and reducing downtime, continuous manufacturing helps lower operational costs. With more efficient production, companies can scale more easily and allocate resources more effectively.

Industry Adoption and Growth

Pharmaceutical manufacturers are investing in continuous manufacturing to enhance efficiency and stay competitive. As more companies make the switch, the industry is moving toward a future where flexible, scalable, and high-throughput production becomes the standard.

Opportunities for Equipment Suppliers, Service Providers, and Engineers

Equipment Suppliers: Powering the Shift

Manufacturers need advanced machinery designed for uninterrupted production. Companies that provide innovative solutions will play a key role in enabling this transition.

Service Providers: Facilitating Implementation

Transitioning to continuous manufacturing requires specialized expertise in process development, regulatory compliance, and validation. Service providers who can guide companies through this transformation will be in high demand.

Engineering Firms: Designing the Future

Adapting facilities for continuous manufacturing means rethinking layouts, integrating automation, and ensuring seamless process flow. Engineering firms that focus on these challenges will be at the forefront of pharmaceutical manufacturing’s next phase.

Challenges: Navigating Regulatory and Infrastructure Changes

Regulatory Compliance

Regulatory agencies recognize the benefits of continuous manufacturing, but companies must carefully navigate evolving guidelines. Engaging with regulators early in the transition can help streamline approvals and ensure compliance.

Facility Upgrades

Many pharmaceutical plants were built for batch processing, making the transition to continuous manufacturing a significant undertaking. Upgrading infrastructure, implementing new technologies, and training employees are all essential steps for a successful shift.

The Future of Continuous Manufacturing

As automation and digital technologies continue to advance, continuous manufacturing will become even more efficient and accessible. The companies that embrace this evolution now will be best positioned for success in the years ahead.

Ready to Make the Transition?

Continuous manufacturing is more than a trend, it’s the future of pharmaceutical production. Hygenix helps businesses navigate this shift with tailored solutions for equipment suppliers, service providers, and engineering firms. Whether you're upgrading existing systems or starting fresh, we’re here to help.

Contact us today to learn how your company can benefit from continuous manufacturing.