Part 2

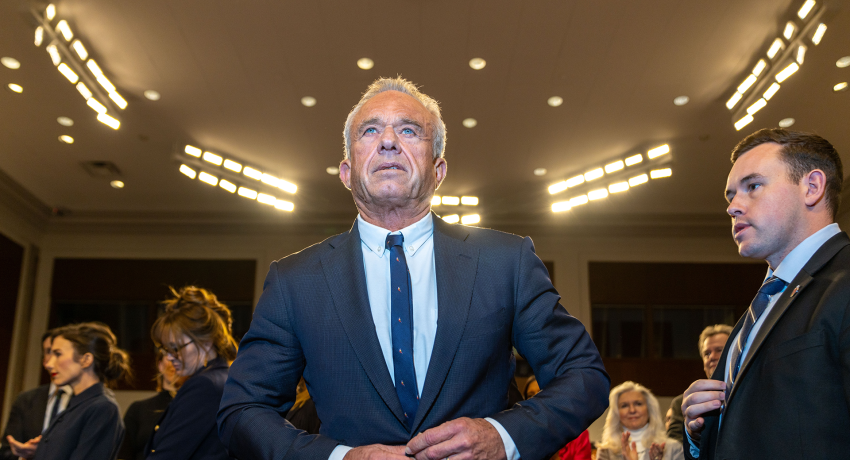

In a previous post, we outlined how Robert F. Kennedy Jr., as Secretary of Health and Human Services, planned to overhaul the FDA’s approval process for rare disease treatments. That policy shift is no longer speculative. The FDA is already implementing those changes.

Robert F. Kennedy Jr., now serving as Secretary of Health and Human Services, has made it clear: the FDA will accelerate the review of treatments for rare diseases. On June 5, Kennedy reiterated his intention to “eliminate the regulatory barriers to drug development” and accelerate approvals through policy shifts already underway at the agency (Reuters).

These are not just campaign talking points. The FDA’s Center for Biologics Evaluation and Research has begun operationalizing a framework for faster approvals, relying more heavily on surrogate endpoints and real-world evidence. Manufacturers with viable platforms for orphan diseases should already be planning for compressed development timelines and earlier entry into production.

This shift affects more than biopharma firms. Equipment suppliers, contract manufacturers, engineering partners, and service vendors supporting regulated facilities should prepare for a sharp increase in demand from clients pursuing accelerated approval paths.

Manufacturers Face Execution Risk Without a Strategic Plan

Early access policies will expedite the commercialization of therapies, but the risk of underestimating operational timelines is real. Facility readiness, commissioning sequences, and equipment procurement windows were already stressed. FDA acceleration will compress schedules further.

Manufacturers need to assess where their current plans no longer align with regulatory reality. For many, that means revisiting capacity assumptions, qualification lead times, and organizational readiness across internal and outsourced functions.

Equipment Suppliers Need to Model Demand Waves Now

OEMs and distributors that serve fill-finish, aseptic processing, and advanced therapy markets will see more inbound RFQs, but not always with realistic delivery timelines. Strategic planning is essential. Lead times for isolators, HVAC-integrated suites, and packaging equipment are already long. Some suppliers may need to reconfigure inventory approaches or evaluate which clients are best aligned for collaborative planning.

Service Providers Must Prepare to Execute on Compressed Timelines

Commissioning agents, calibration teams, utility designers, and training providers should expect more projects with nontraditional start dates and accelerated punch lists. That means reshaping how capacity is scheduled, how staff are allocated, and how deliverables are staged across client portfolios. Firms that can’t adapt may get outpaced by those who’ve already shifted into proactive planning cycles.

Hygenix Helps Teams Get Aligned Before It’s Too Late

Hygenix supports manufacturers and their extended project teams across planning, execution, and delivery. We help identify gaps early and align capital, talent, and vendor resources to meet evolving demand.

- Planning: We collaborate with internal teams to pressure-test their assumptions and validate their findings. We help outline project scopes, resource requirements, and timelines that align with the new regulatory horizon. See more on Planning.

- Managing: Hygenix oversees multi-party execution strategies across design, procurement, qualification, and operational readiness. This approach ensures accountability and continuity across all functions. See more on Managing.

- Delivering: As projects transition from planning to execution, we remain engaged to track milestones, manage deviation risks, and ensure delivery aligns with regulatory timelines. See more on Delivering.

The FDA is already shifting policy in rare disease drug approvals. This change will drive upstream manufacturing and facility demand across the United States. The companies that build plans now, before the wave crests, will be positioned to lead.

If you’re looking for a partner to help you prepare, get in touch.